Description:

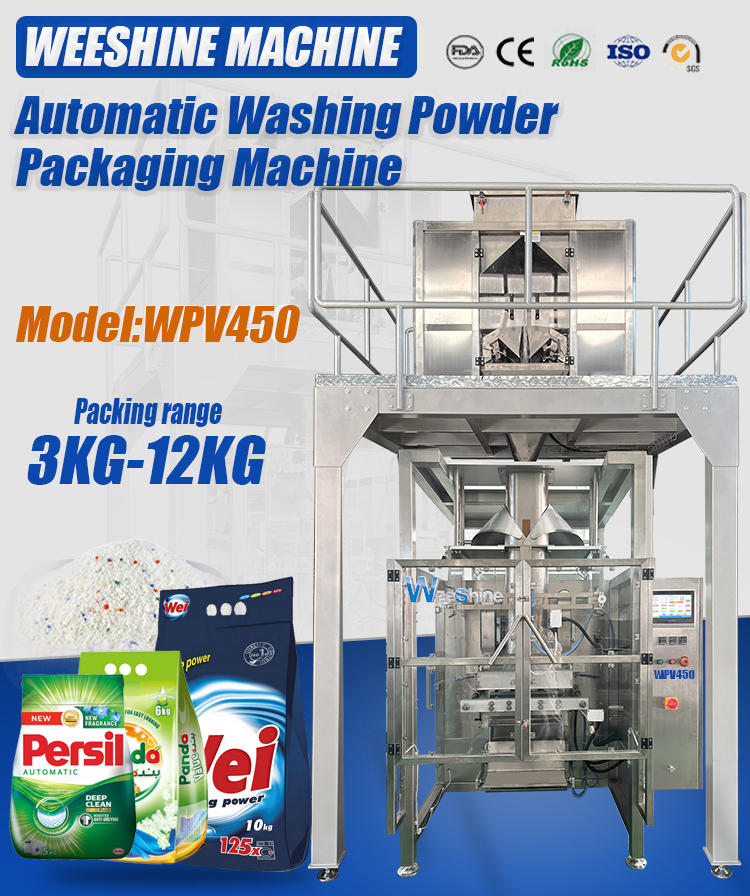

Weeshine WPV450 linear weigher packaging machine, for the production of a very wide range of package. It’s have been designed with one goal in mind: to ensure the safety and integrity of your in-bag products. With our cutting-edge technology, you can rest assured that your products will be perfectly packaged every time

Automatically package salt,sugar,spices,rice,seeds,flavoring , chemical,washing powder,and other small particle that needs automatic bagging.

Working Principle:

- Forming the Bag: The machine unwinds a roll of flat plastic film, which is then guided by a forming tube. This tube shapes the film into a pouch of the desired size.

- Filling the Bag: Once the pouch is formed, it’s held open by a clamp. The product is then dispensed into the open pouch using a variety of filling mechanisms depending on the product characteristics. This could be by weight, auger, pump, or volumetric cup depending on the product’s consistency.

- Sealing the Bag: After filling, the pouch is heat-sealed closed at the top. Some machines can also create a seal at the bottom of the pouch, depending on the desired style (e.g., pillow pouch vs. doy pouch).

- Trimming and Completing the Package: After sealing, the pouch is cut from the remaining film. The finished package can then have additional features added, such as a date code, a tear notch for easy opening, or a hole punch for hanging.

This simple and economical packaging machines is engineered for applications requiring flexibility, shorts runs, for hand or auto loading. Using non-proprietary flat roll stock film, pouch will be produced with top and bottom seals and a vertical back seal. This versatile bagger is easy to use, easy to clean and takes up very little space.

Main Features:

- Equipped with safety protection,comply with firm’s safety management requires.

- PLC and HMI controller, easy to operate and maintain.

- Servo film pulling system,photocell accuracy cutting position.

- Touch screen can store the technical parameters of various kinds of products.No need to reset while products changing.

- Separate circuit boxes for power control and pneumatic control, low noise, good tightness and more stable.

- Automatically completed products feeding,forming, filling, gas flushing (exhausting), sealing,cutting,date printing and counting.

- Have error indicating system, helping handle the trouble immediately.

- The device of gusseted bag, linked bag, punching device ect for optional.